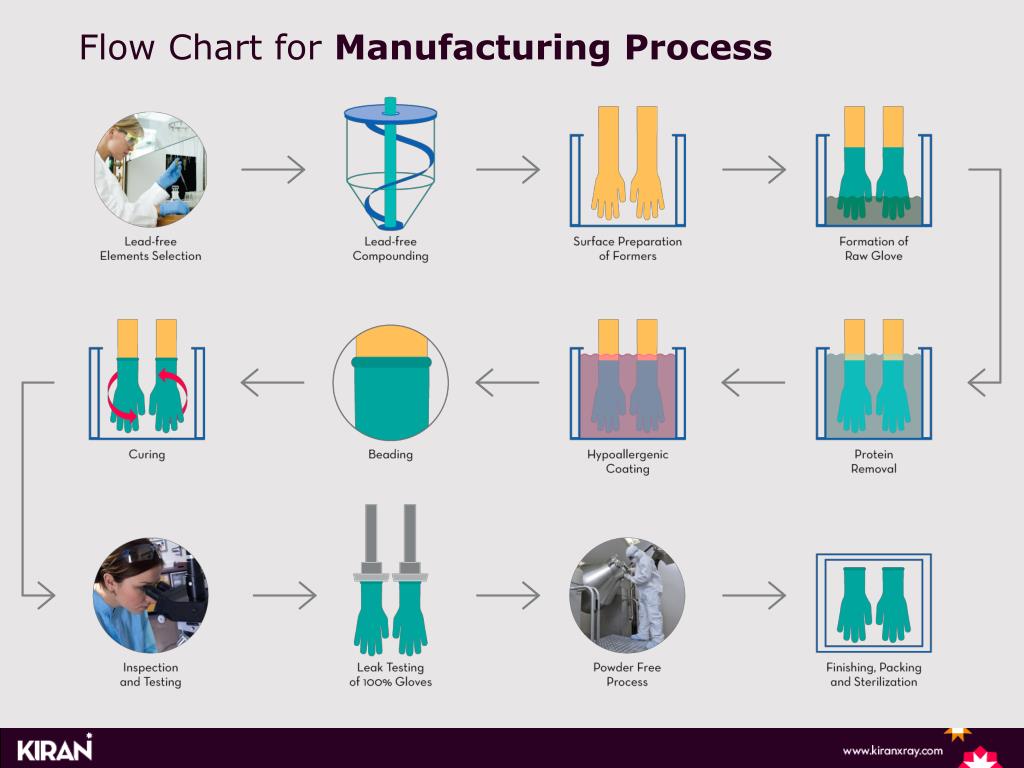

Figure 1.Manufacturing is a process that entails the creation of goods for consumer purchase. Follow-up helps to detect the problems and remove them to help with the smooth functioning of the process.

Follow-up measures the actual versus the expected productions. It may involve the provision of necessary items, the maintenance of records, the monitoring of workflows as planned, the recording of the number of times a machine works, machine idling time, etc.įollow-up: Follow-up is the last stage of the production process. For example, how much time should each stage of production involve? How long should each person work on a particular workflow?ĭispatching: This stage is the actual start of the production. Scheduling: Scheduling means deciding the timings of the production process. This is a crucial stage in the production process. Decisions are made regarding the quantity and quality of goods and services as well as on the place of production. Routing: This is the next stage in the production process where the raw materials may be procured, processed, finished, quality checked, and distributed. This stage helps to define the purpose and how the goals of production can be achieved properly. Planning: usually the basic requirement of all production processes. However, these may vary from industry to industry. The following are generally the basic stages that are involved in most of the production processes. There are multiple ways to create a production process flow chart, depending on the organization’s need and their production line. The production process goes through various stages, which can be understood with the help of the flow chart. If all of the above factors of production are in place, the production process of biscuits runs smoothly and can match the requirement of the business and customers. The company will also need labour to mix all the ingredients together, separate them into batches of production and different flavours, set the output levels of the machines and temperature of the ovens, decide on the labeling function, and oversee the overall production system.Īnother important function and need of the production process is technology to ensure the labels are correct, the names of the product are rightly mentioned, the temperature is set correctly, and all other necessary technical aspects that do not require human intervention. In addition, it will need machinery for making the biscuits' packaging and labelling, which will all become capital investment for the company. It will also need an oven to bake the biscuits. Secondly, in the production of biscuits, the organization will need the machines to mix all the necessary ingredients. To set up this production process, the company requires a place or land to set up the whole production unit. Let's explore the production process with the example of biscuit production. Land refers to natural resources such as land, energy, etc., that are used in the process of production and are counted under the category ‘land’. Technology refers to the technology used in the production process, whether the kind of machinery, the programming of machinery, the capacity of machinery, etc. Labour refers to the people involved and the time and effort that were put into the process. Investment can be in terms of monetary investments or assets like machines, vehicles, etc. The factors of production are explained in detail below:Ĭapital includes the amount invested in the process of production.

Risks and Rewards of Running a Business.Evaluating Business Success Based on Objectives.Information and Communication Technology in Business.Effects of Interest Rates on Businesses.Improving Employer - Employee Relations.

0 kommentar(er)

0 kommentar(er)